Rvng RaceWorks: High Temp Coatings Built to Withstand Extreme Heat

Understanding High Temp Coatings

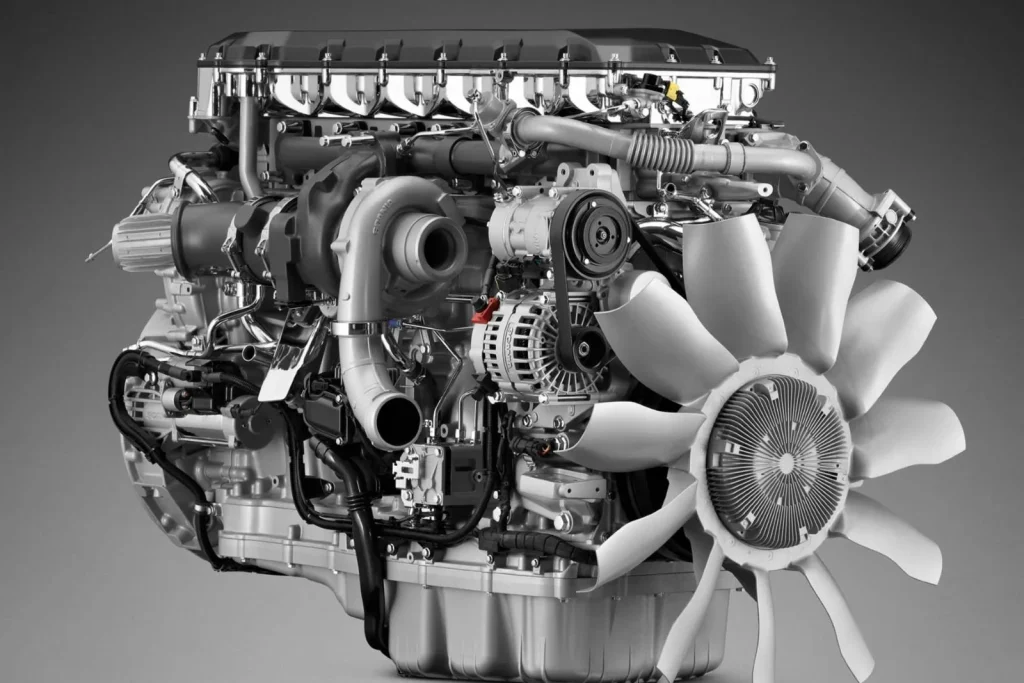

High temp coatings are specialized solutions designed to endure extreme temperatures. At Rvng RaceWorks, we focus on providing High temp coatings that protect engines, exhaust systems, and industrial equipment from heat-related damage. Unlike standard coatings, high temp options maintain their integrity and performance even under the most severe thermal conditions.

Why High Temp Coatings Matter

In environments where temperatures regularly exceed 500°F, standard paints and finishes fail quickly. High temp coatings provide a reliable layer of protection, reducing wear and tear, corrosion, and oxidation. Rvng RaceWorks ensures that every high temp coating we offer meets rigorous performance standards for both durability and safety.

Applications of High Temp Coatings

High temp coatings are essential in several industries. They are widely used in automotive, aerospace, and manufacturing sectors. At Rvng RaceWorks, our high temp coatings are applied to:

- Engine components

- Exhaust systems

- Turbochargers

- Industrial machinery

- Heat shields

These coatings prevent material degradation caused by prolonged exposure to high temperatures, ensuring longer lifespan and improved performance.

Types of High Temp Coatings

Ceramic High Temp Coatings

Ceramic-based high temp coatings provide superior heat resistance and excellent thermal insulation. They reduce heat transfer, protecting underlying materials from damage. Rvng RaceWorks offers ceramic high temp coatings suitable for engines and exhaust systems, which are exposed to extreme thermal cycles.

Silicone-Based High Temp Coatings

Silicone-based high temp coatings are known for flexibility and adhesion at elevated temperatures. They resist cracking, peeling, and flaking even in high-stress conditions. Using these coatings ensures that components remain functional and visually appealing over time.

Epoxy-Based High Temp Coatings

Epoxy high temp coatings are ideal for industrial applications. They provide chemical resistance along with thermal protection, making them perfect for machinery operating under extreme heat. Rvng RaceWorks applies epoxy high temp coatings to protect sensitive equipment efficiently.

Benefits of Using High Temp Coatings

High temp coatings offer several advantages for performance and durability:

- Heat Resistance: They maintain their structure and performance at extreme temperatures.

- Corrosion Protection: High temp coatings prevent rust and oxidation.

- Longevity: Components coated with high temp materials last longer under harsh conditions.

- Enhanced Performance: Engines and machinery operate more efficiently with reduced thermal stress.

- Cost Savings: High temp coatings reduce maintenance needs and replacement costs.

Choosing the Right High Temp Coating

Selecting the appropriate high temp coating depends on temperature range, surface material, and exposure environment. Rvng RaceWorks provides expert guidance to help clients choose coatings that maximize protection and performance. Factors to consider include:

- Maximum operating temperature

- Exposure to chemicals or moisture

- Surface preparation requirements

- Coating thickness and curing process

How Rvng RaceWorks Applies High Temp Coatings

Proper application of high temp coatings is critical for effectiveness. At Rvng RaceWorks, we follow precise procedures:

- Surface Preparation: Cleaning and sanding surfaces to ensure adhesion.

- Application: Using spray or brush methods for uniform coating.

- Curing: Heating components to allow high temp coatings to bond permanently.

- Inspection: Ensuring coating integrity and coverage.

High Temp Coatings in Automotive Performance

Automotive enthusiasts and professional racers rely on high temp coatings for performance and longevity. Exhaust headers, turbo components, and engine blocks experience extreme heat cycles. Applying high temp coatings from Rvng RaceWorks improves thermal management, reduces heat soak, and protects critical parts from degradation.

Maintenance Tips for High Temp Coatings

High temp coatings are durable but require proper care. Regular inspections and cleaning with non-abrasive materials help maintain the coating’s integrity. Avoid harsh chemicals that could damage the protective layer. Rvng RaceWorks provides maintenance guidelines to ensure high temp coatings last longer and perform optimally.

The Rvng RaceWorks Advantage

Choosing Rvng RaceWorks for high temp coatings guarantees:

- High-quality, industry-tested materials

- Expert application for maximum protection

- Tailored solutions for automotive, industrial, and aerospace needs

- Extended component life and improved performance

With over a decade of experience, Rvng RaceWorks specializes in high temp coatings that withstand extreme conditions, providing customers with reliable and long-lasting solutions.

Conclusion

High temp coatings are essential for anyone dealing with extreme heat in engines, machinery, or industrial equipment. Rvng RaceWorks delivers high temp solutions that combine durability, performance, and protection. By choosing the right high temp coating, you can enhance efficiency, extend component life, and reduce maintenance costs. Trust Rvng RaceWorks to provide high temp coatings that perform under the harshest conditions.